Wenger Engineering

Wenger Engineering from Ulm, Germany is a leading global technology developer for hydrogen technology, renewable energies and energy efficiency.

Why Wenger Engineering?

Technology for pioneers.

Since 2007, we have been working as a development partner for global corporations, leading medium-sized companies, ambitious startups and research institutes on six continents.

In more than 750 projects, our customers have been primarily focused on one thing: moving the state of the art to make the energy transition possible.

Let’s talk about how we can work together to raise your state of the art to a whole new level.

Hydrogen Technology

Simulation

Systems Engineering

Product Development

Renewable Energies

Plant development

Plant optimization

System simulation

Energy Efficiency

Heat transfer

Flow simulation

Heat recovery

Our customers

Some of our 342 customers

Project examples

Experience from more than 750 projects for 342 customers

Hydrogen laboratory strategy workshop

Strategy consulting for a joint venture of medium-sized companies to design and establish a joint hydrogen laboratory for their own product developments.

Client: Joint venture of hidden champions

Country: Germany

Conceptual design of hydrogen refueling stations for trucks

Concept study and simulations for optimal dimensions of hydrogen refueling stations for trucks with 350 bar and 700 bar.

Customer: Oil company

Country: England

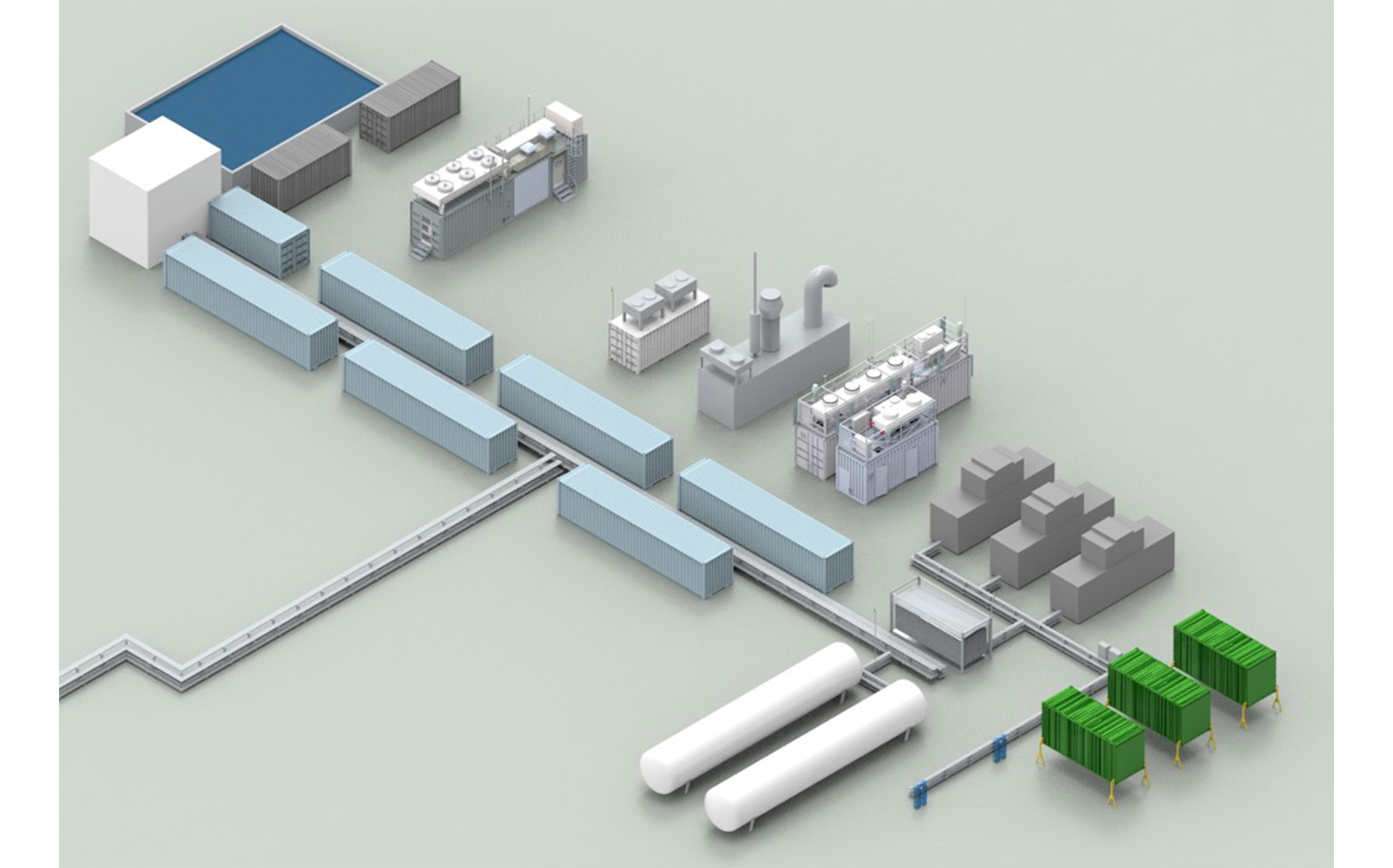

Development and construction of electrolysis test center

Development and construction of the world’s largest electrolysis test center with up to 8MW electrolysis capacity, fuel cell, H2 CHP, trailer filling stations, etc.

Customer: Research institute

Country: Germany

Testimonials

“Wenger Engineering’s highly competent employees deliver high-quality results. Added to this is their flexibility, which plays a major role in ensuring a pleasant cooperation. This collaboration is proving very helpful in our projects.”

“The exchange with Wenger Engineering GmbH has been very positive! We worked together to come up with a clear strategy! I really appreciate their hard work.”

“I just wanted to personally thank you for a job well done on the simulation work. We learned a lot through this process and I can honestly say that without Wenger’s simulation tool and the expertise of the Wenger Engineering team, we could not have achieved our goal. I hope we have the opportunity to work together on future projects.”

Dr.-Ing. David Wenger, Founder and CEO

Based in Ulm, Germany, Wenger Engineering GmbH, together with its sister company Wenger Hydrogen GmbH, is a leading global expert in hydrogen plants, power-to-gas facilities and refueling stations.

With more than 18 years of experience and over 750 hydrogen projects worldwide, founder and owner David Wenger is one of the top authorities in the field, with particular expertise in hydrogen infrastructure.

45,000 people from over 100 countries read David Wenger’s email blog every week.

Sign up to be infotained on hydrogen technology, renewables and energy efficiency.

By clicking on “Register” you agree to the use of your data within the framework of our data protection declaration. Your data is safe with us and will be treated confidentially.

Contact us

Visit us

Wenger Engineering GmbH

Einsteinstraße 55

89077 Ulm

Germany

Call us

+49 731 79 06 05-0

Write us

mail(at)wenger-engineering.de